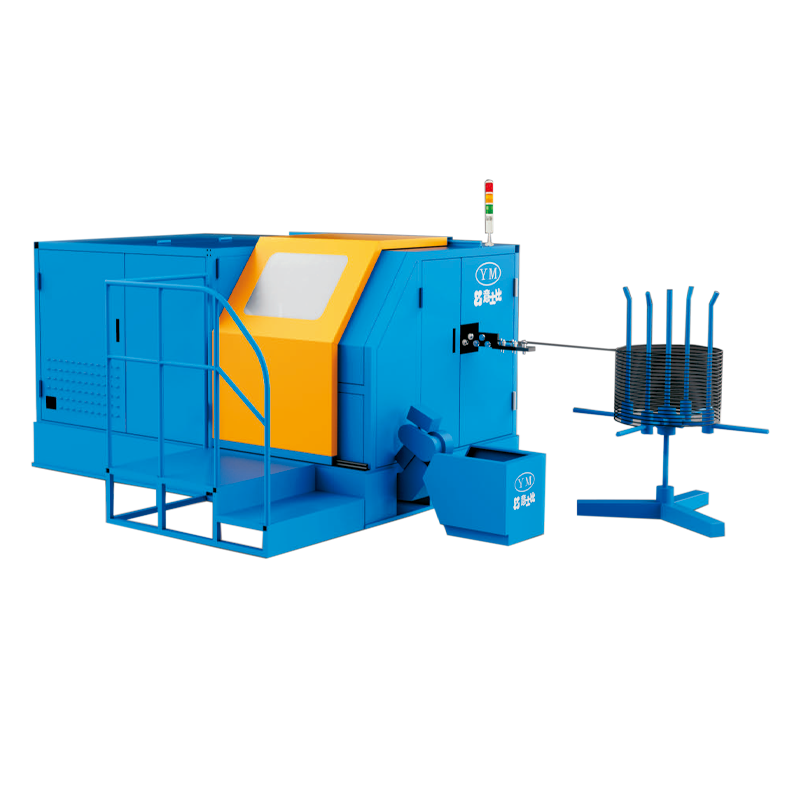

Our state-of-the-art 4-mode 4-punch station high-speed bolt cold pier machine and riveting machine represent the pinnacle of screw manufacturing technology. Engineered with precision and efficiency in mind, this machinery sets a new standard for the industry, providing a comprehensive solution for high-speed bolt production.

specifications:

| Model | Unit | K-404 | K-405 | KD-406 | KD-408 | KD-410 | KD-413 |

Forging station | NO. | 4 | 4 | 4 | 4 | 4 | 4 |

Forging force | Kgf | 22000 | 32000 | 50000 | 7000 | 10500 | 140000 |

| Max.cut-off dia | mm | Ø5 | Ø7 | Ø8 | Ø10 | Ø12 | Ø16 |

| Max.cut-off length | mm | 45 | 90 | 100 | 140 | 165 | 220 |

Production speed | pcs/min | 280 | 260 | 220 | 200 | 180 | 120 |

| Master die ejection stroke | mm | 40 | 70 | 90 | 130 | 145 | 200 |

| Punch die ejection stroke | mm | 20 | 20 | 30 | 40 | 40 | 60 |

Main sliding table stroke | mm | 100 | 120 | 130 | 160 | 195 | 270 |

| Overall dims.Of mian die | mm | Ø35*60 | Ø50*90 | Ø50*100 | Ø60*130 | Ø75*135 | Ø86*190 |

| Overall dims.Of punch die | mm | Ø31*85 | Ø38*85 | Ø40*100 | Ø45*125 | Ø55*115 | Ø60*130 |

Overall dims.Of cut of die | mm | Ø18*25 | Ø28*35 | Ø28*40 | Ø40*60 | Ø45*60 | Ø63*69 |

Die pitch | mm | 50 | 55 | 60 | 80 | 90 | 110 |

Applicable bolt die | mm | 1-4 | 2-5 | 3-6 | 4-8 | 6-10 | 8-16 |

| Shank lenght of blank | mm | 10-40 | 10-65 | 10-85 | 10-115 | 10-115 | 20-180 |

| Max flange dia | mm | Ø9.5 | Ø17 | Ø17 | Ø19 | Ø23 | Ø28 |

Main engine motor | KW | 5.5 | 18.5 | 22 | 30 | 37 | 55 |

| Machine weight | Kgs | 3500 | 6500 | 8000 | 14000 | 21000 | 31000 |

Machine dimension | mm | 2600*1800*1400 | 3500*2000*2000 | 3500*2000*2000 | 3630*2350*2090 | 4100*2500*2200 | 10500*3950*3050 |

Advantages:

Unprecedented Productivity:

Integrates four high-speed workstations, maximizing production capacity and efficiency in bolt manufacturing.

Advanced Cold Piercing Technology:

Features cutting-edge 4-mode 4-punch station technology for unparalleled precision in cold piercing, ensuring consistent and top-quality screw production.

Versatile and Customizable:

Adaptable to a diverse range of screw types, materials, and specifications. The machine can be customized to meet specific production requirements, offering flexibility in operations.

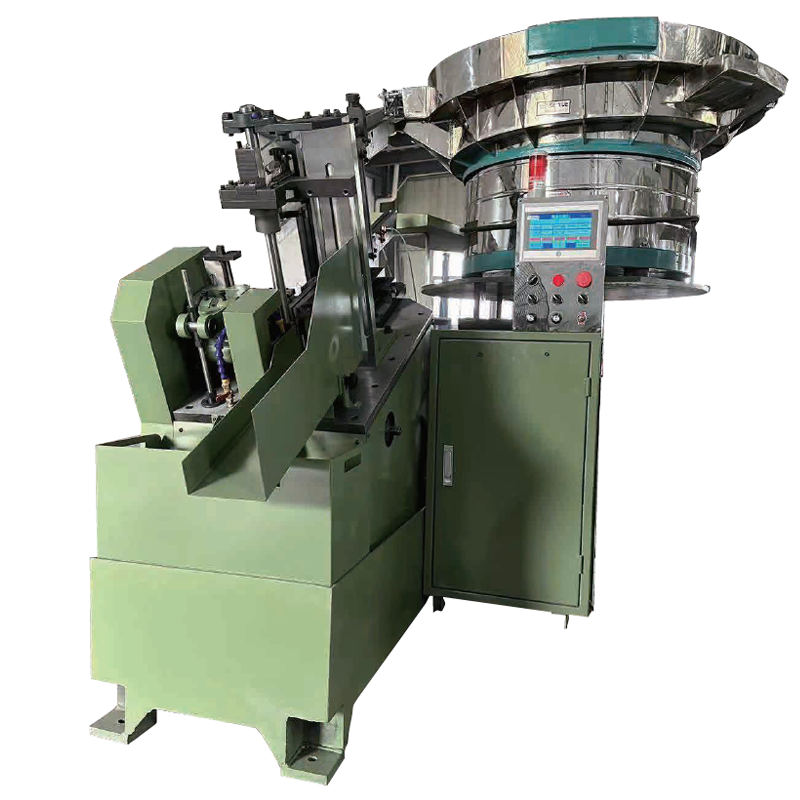

Efficient Riveting Capability:

Equipped with advanced riveting functionality, expanding its utility beyond cold piercing to cover various aspects of screw assembly.

Detail Image:

Applications:

Tailored for large-scale screw production in industries such as automotive, aerospace, electronics, and construction.

Ideal for manufacturing screws with complex geometries, diverse materials, and stringent quality requirements.

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

Frequently Asked Questions (FAQ):

Q: What types of screws can be produced using this machine?

A: The machine is designed to manufacture a broad spectrum of screws, including standard, specialty, and customized screws to meet diverse industry demands.

Q: How does the 4-mode 4-punch station technology contribute to improved production outcomes?

A: This advanced technology ensures the highest level of precision in cold piercing, resulting in consistent product quality and increased manufacturing efficiency.

Q: Is the machine user-friendly and easily operable?

A: Yes, our machine boasts an intuitive control system and a user-friendly interface, making operation straightforward. Training and technical support are provided to facilitate smooth usage.

Q: Can the machine be customized to suit specific production requirements?

A: Absolutely. We offer customization options to tailor the machine to your unique production needs, providing flexibility and optimal performance.

Q: In which industries is this machine most beneficial?

A: Industries such as automotive, aerospace, electronics, and construction that require efficient and high-speed screw manufacturing processes can significantly benefit from this advanced machinery.