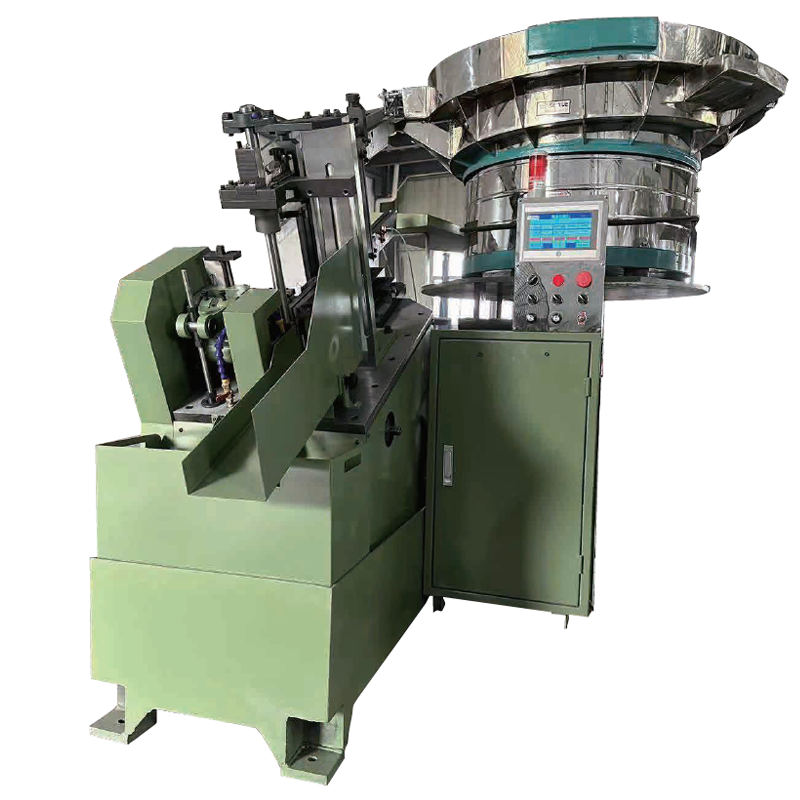

The HIGH SPEED SCREW TAIL CUTTING MACHINE - HH-C100 Machine is designed for maximum efficiency and precision in the production of self-drilling screws. Engineered with advanced technology, this machine offers rapid operation and exceptional reliability, ensuring high-quality output with minimal downtime.

PRODUCT PARAMETERS

Dimension:L1700*W800*H1300(mm)

Mechanical weight:1000KG

Horsepower: Motor2HP.1.5KW 1/2HP.0.75KW/1/8HP

Manufacturing range: die 2.5-8.0, length 10-100mm

Speed: 100-400PCS/min

Control method: Programmable PLC

Vibration disc lifting method: manual lifting

Key Features:

TAdopting Taiwan's high-speed precision intermittent splitter, stable and efficient performance

The use of a touch screen display screen is easy to operate, and in case of a malfunction, the screen

can display an alarm directly, making maintenance and repair convenient

Advantages:

Precision and Consistency: Achieve precise and consistent thread rolling for high-quality screw threads.

Efficiency: High-speed production capabilities contribute to increased manufacturing efficiency and output.

Versatility: Adapt to various screw sizes and specifications, providing flexibility in production.

Durable Design: Robust construction ensures long-term reliability and stability in demanding manufacturing environments.

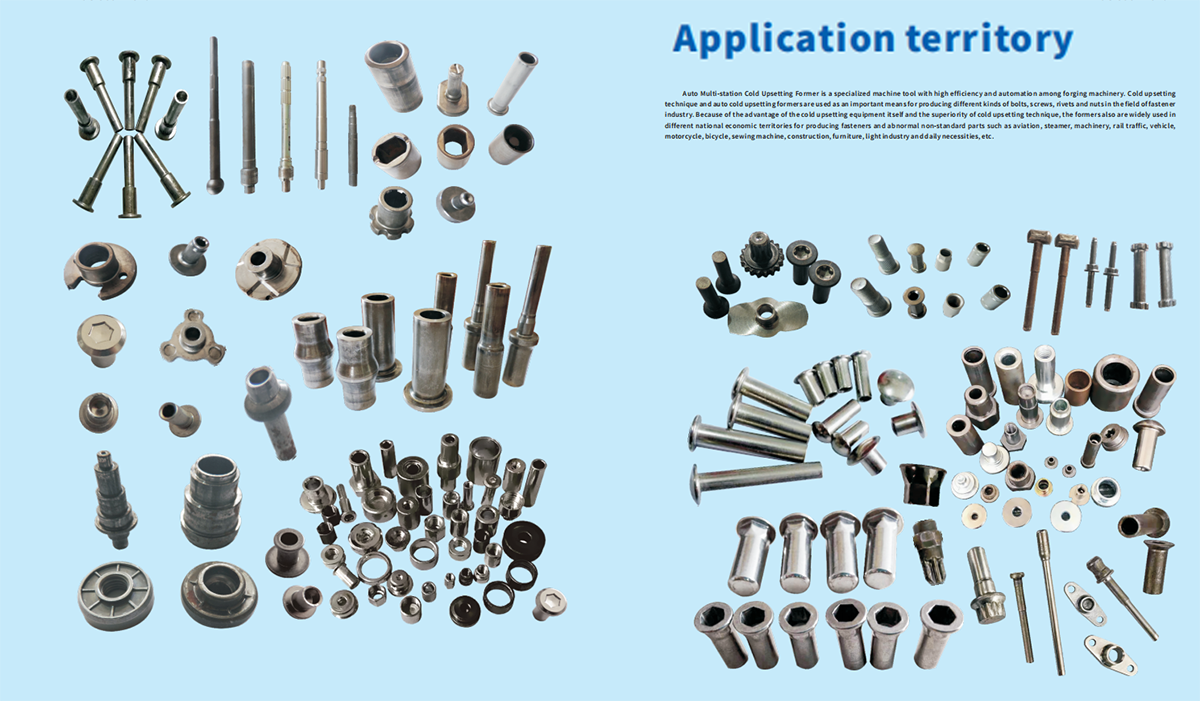

Applications:

The HIGH SPEED SCREW TAIL CUTTING MACHINE - HH-C100 is an essential tool for manufacturers in the fastener industry. It finds applications in various sectors, including construction, automotive, aerospace, and machinery manufacturing. The machine is versatile, catering to a wide range of screw production needs.

![1728695330669115.png ]87Q%G0%48{MQ91~XE@_VRV.png](/static/upload/image/20241012/1728695330669115.png)

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

Frequently Asked Questions (FAQ):

Q: What types of screws can be produced with this machine?

A: The Thread Rolling Machine is versatile and can be adjusted to produce a variety of screws, accommodating different sizes and specifications.

Q: How fast is the production speed of the machine?

A: The machine is engineered for high-speed production, significantly increasing efficiency and output.

Q: Can the machine be customized for specific thread types?

A: Yes, the machine is designed with adjustable settings to meet the specific requirements of different thread types and sizes.

Q: Is training required to operate the machine?

A: The machine features a user-friendly interface, and minimal training is required for operators to efficiently run and manage the production process.