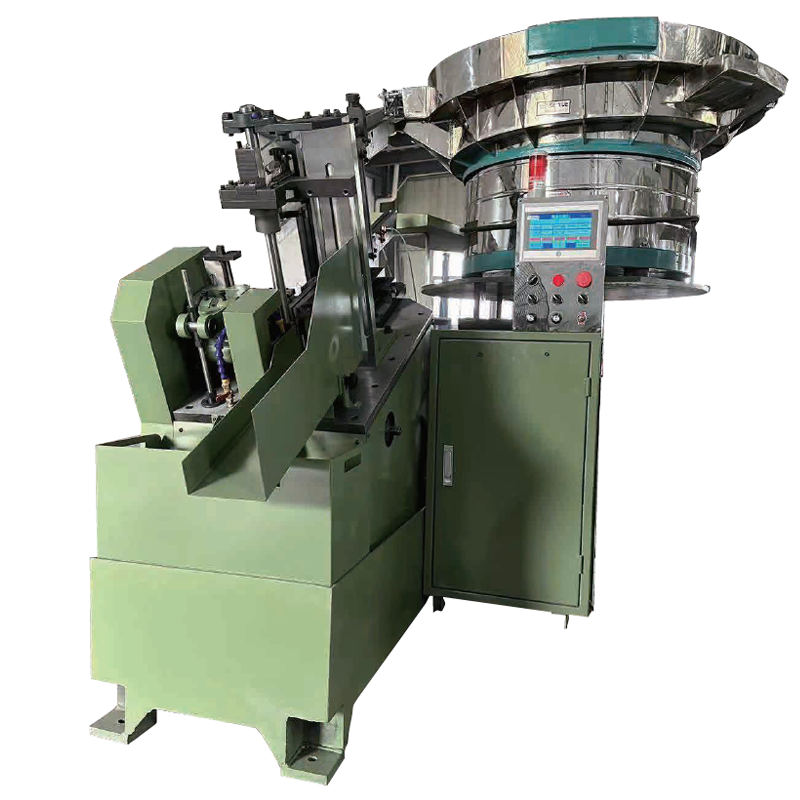

Introducing our cutting-edge Screw Heading Machine—a state-of-the-art solution at the forefront of screw manufacturing technology. This advanced machine is designed for precision and efficiency in the heading process, ensuring high-quality screw production for various applications. Elevate your manufacturing capabilities with this innovative solution.

specifications:

| Specification | AE-5H-65 | AE-6H-80 | AE-6H-100 |

Max wire diameter | 5mm | 5mm | 8mm |

Max blank length | 65mm | 80mm | 100mm |

Speed | 140-160PCslmi | 100PCs/min | 9OPCs/min |

Size | L2080"W1060*H1120m | L2800*W1150*H1270mm | L3050*W1150*H1270mm |

| Power | 3kw | 4kw | 4kw |

| Weight | N.w.1800KG | N.w.2500KG | N.w.2800KG |

Key Features:

Precision Heading Technology:

Incorporates advanced heading technology for precise and consistent formation of screw heads.

Ensures uniformity and accuracy in the manufacturing process.

High-Speed Production:

Engineered for high-speed production, significantly increasing manufacturing efficiency.

Enhances overall productivity while maintaining precision.

Versatile Screw Production:

Designed to accommodate a wide range of screw sizes and types.

Adjustable settings for quick customization, meeting diverse manufacturing requirements.

User-Friendly Interface:

Equipped with an intuitive control panel for easy operation and monitoring.

Requires minimal training for operators to efficiently run and manage the machine.

Advantages:

Precision and Consistency: Achieve precise and consistent screw heading for high-quality end products.

Efficiency: High-speed production capabilities contribute to increased manufacturing efficiency and output.

Versatility: Adapt to various screw sizes and specifications, providing flexibility in production.

User-Friendly Operation: Intuitive interface ensures easy operation and reduces the learning curve for operators.

Applications:

The Screw Heading Machine is an essential tool for manufacturers in the fastener industry. It finds applications in various sectors, including construction, automotive, electronics, and furniture manufacturing. The machine is versatile, catering to a wide range of screw production needs.

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

Frequently Asked Questions (FAQ):

Q: What types of screws can be produced with this machine?

A: The Screw Heading Machine is versatile and can be adjusted to produce a variety of screws, accommodating different sizes and specifications.

Q: How fast is the production speed of the machine?

A: The machine is engineered for high-speed production, significantly increasing efficiency and output.

Q: Can the machine be customized for specific screw types?

A: Yes, the machine is designed with adjustable settings to meet the specific requirements of different screw types and sizes.

Q: Is training required to operate the machine?

A: The machine features a user-friendly interface, and minimal training is required for operators to efficiently run and manage the production process.