Introducing our cutting-edge High-Speed Intelligent Self Drilling Screw Point Forming Machine—a pinnacle of precision engineering for the manufacturing of self-drilling screws. This advanced machine combines speed, intelligence, and versatility to revolutionize the production process, setting new standards for efficiency and quality.

specifications:

| Model & Specification | AE5125 |

Capacity | 4#-12#(OD:2.9-5.5mm), L10-125m |

Speed | 100-500PCS/min |

Power | 7.5KW (10HP) Inverter,5.5KW (7.5HP.6P) Moto |

Control system | PLC(Program Logical Control) |

| Detection system | Touch Screen Human-Machine Interface Error DisplayAutomatic on-linedetectionAccurate error alarm |

| Transmission | INDEX |

| Dimension(L*W*H) | L1900*W1400*H1800mm |

| Machine Weight | 2300KG |

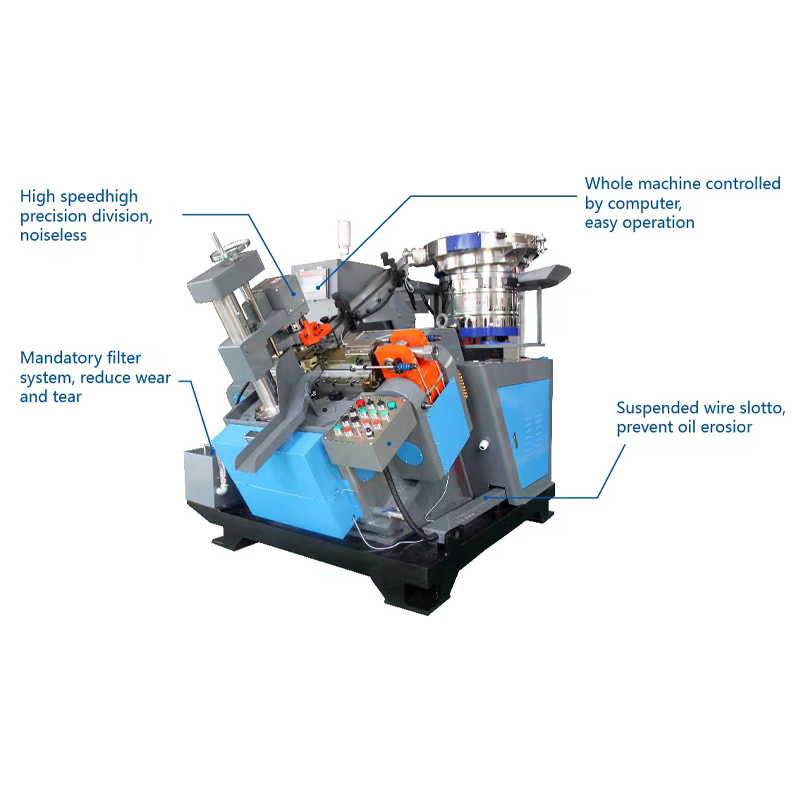

Key Features:

High-Speed Precision Forming:

Utilizes state-of-the-art technology for rapid and precise formation of self-drilling screw points.

Engineered for high-speed production, significantly boosting manufacturing efficiency.

Intelligent Control System:

Features a sophisticated control system for automated production, real-time monitoring, and adjustment of key process parameters.

Enhances product consistency and adaptability to various screw specifications.

Versatile Screw Production:

Designed to accommodate a broad range of self-drilling screw sizes and types.

Adjustable settings for customization, meeting diverse manufacturing requirements.

Sturdy and Durable Construction:

Built with a robust mechanical structure to ensure stability and durability during high-volume production.

Engineered for long-term reliability in demanding manufacturing environments.

Applications:

The High-Speed Intelligent Self Drilling Screw Point Forming Machine is ideal for manufacturers in the fastener industry. It caters to various applications, including construction, automotive, and electronics, providing a versatile solution for the production of self-drilling screws.

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

Frequently Asked Questions (FAQ):

Q: What types of self-drilling screws can be produced with this machine?

A: The machine is versatile and can be adjusted to produce a variety of self-drilling screws, accommodating different sizes and specifications.

Q: How does the intelligent control system contribute to product quality?

A: The intelligent control system continuously monitors and adjusts critical parameters, ensuring consistent and high-quality self-drilling screw production.

Q: Can the machine handle high-volume production?

A: Yes, the machine is specifically engineered for high-speed and high-volume production, meeting the demands of fast-paced manufacturing environments.

Q: Is training required to operate the machine?

A: The machine is designed with user-friendly interfaces, and minimal training is required for operators to efficiently run and manage the production process.