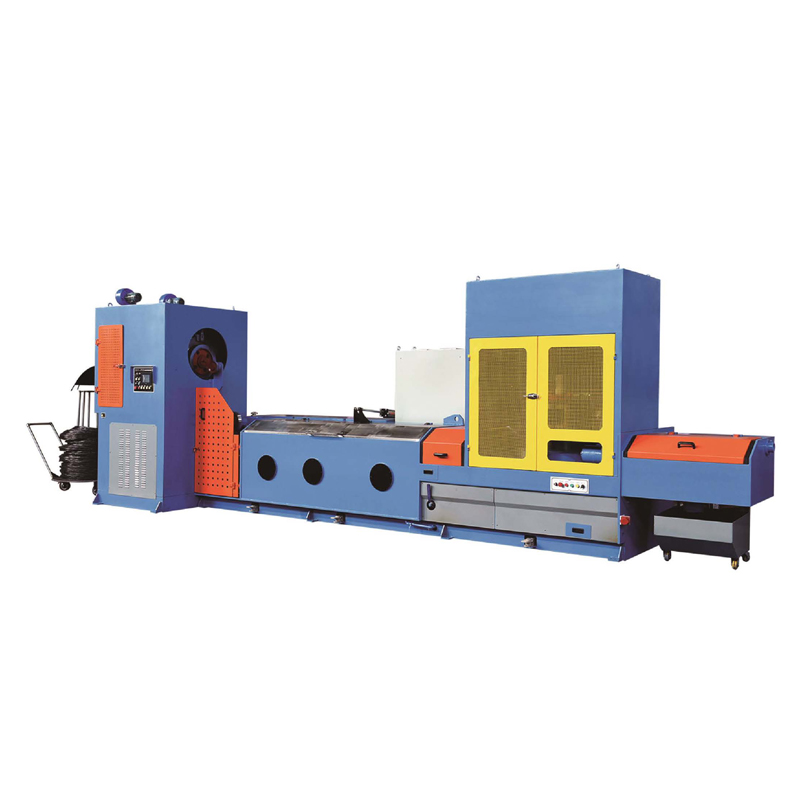

Our Hydraulic Straightening and Cutting Machine is a high-performance industrial solution designed for efficiently straightening and accurately cutting metal rods or wires. This machine is engineered to meet the demands of various industries where precision and speed are essential for optimal productivity.

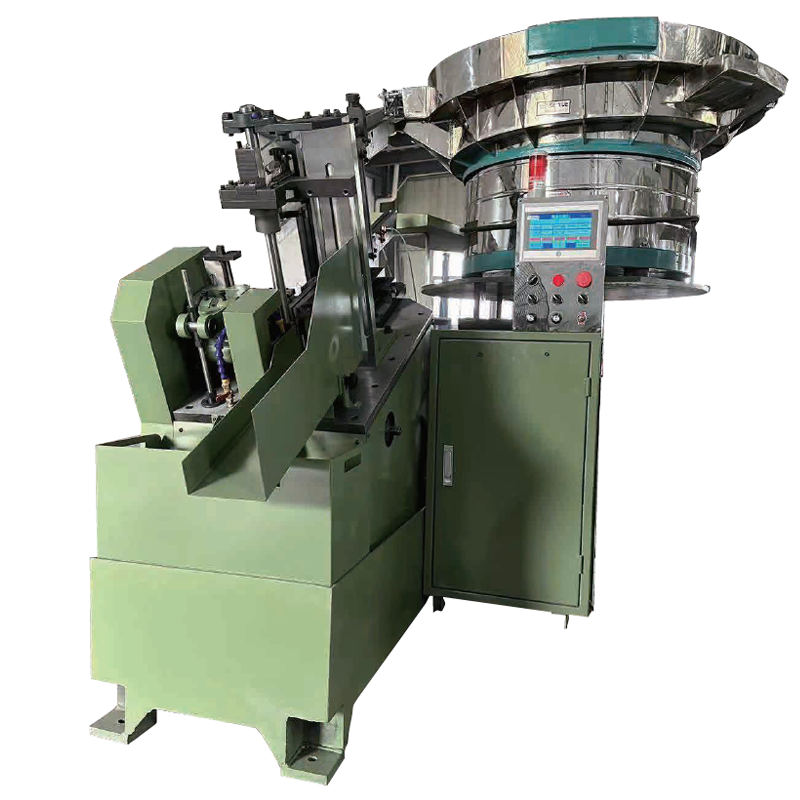

Water Tank Wire Drawing Machine specifications:

LT11/450、LT13/450、LT15/450 | ||||||

Drum's diameter | 450 | 450 | 450 | 450 | 450 | 450 |

Dies number | 11 | 11 | 11 | 13 | 13 | 15 |

Max.diameter of wire inlet | 2.0 | 3.4 | 4.0 | 4.0 | 3.8 | 4.0 |

Min. diameter of wire outlet | 1.2 | 1.5 | 1.9 | 1.6 | 1.5 | 2.0 |

Finished wire speed | 350 | 260-320 | 260-320 | 280 | 280 | 300 |

Motor's power | 30-45 | 30-45 | 30-45 | 30-45 | 30-45 | 30-45 |

Precision Straightening and Cutting:The machine guarantees precise straightening and cutting of metal rods or wires, meeting stringent industry standards.

Hydraulic Power:Utilizes hydraulic power for smooth and consistent operations, ensuring uniform results and reduced material wastage.

Adjustable Settings:Allows operators to easily adjust cutting lengths and straightening parameters to suit different requirements and materials.

High Production Capacity:With efficient straightening and cutting mechanisms, this machine offers high production capacity, enhancing overall productivity.

Safety Measures:Equipped with safety features and mechanisms to ensure a safe working environment for operators, minimizing the risk of accidents.

Durable and Sturdy Construction:Built with durability in mind, the machine features a robust construction using high-quality materials for a long-lasting performance.

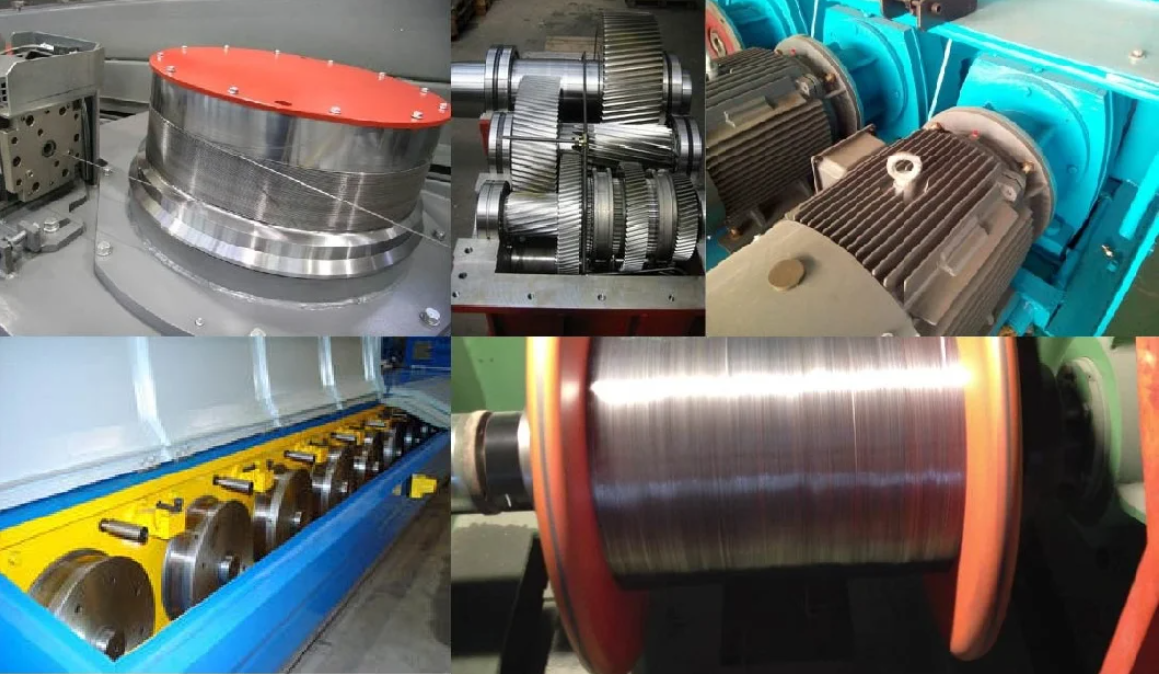

Detail Image:

Finsihed Products:

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

FAQ:

Q1: What types of materials can this machine handle?

A: Our Hydraulic Straightening and Cutting Machine is capable of handling various materials including steel, stainless steel, aluminum, copper, and more.

Q2: Is it possible to customize cutting lengths?

A: Yes, the machine allows for customization of cutting lengths through adjustable settings, catering to specific requirements.

Q3: How do I maintain this machine?

A: Regular maintenance, including lubrication and inspection of key components, is essential for optimal performance. We provide a comprehensive maintenance guide for easy upkeep.

Q4: Can this machine handle continuous production?

A: Yes, the machine is designed for continuous production with efficient straightening and cutting processes to meet high-volume demands. Proper cooling and occasional breaks are recommended for long-term operation.

Q5: Is training provided for operating the machine?

A: Yes, we offer training sessions and detailed operational manuals to ensure operators are proficient in using the machine safely and efficiently.

Q6: What safety features does the machine have?

A: The machine includes safety measures such as emergency stop buttons, protective guards, and safety sensors to ensure operator safety during operation.