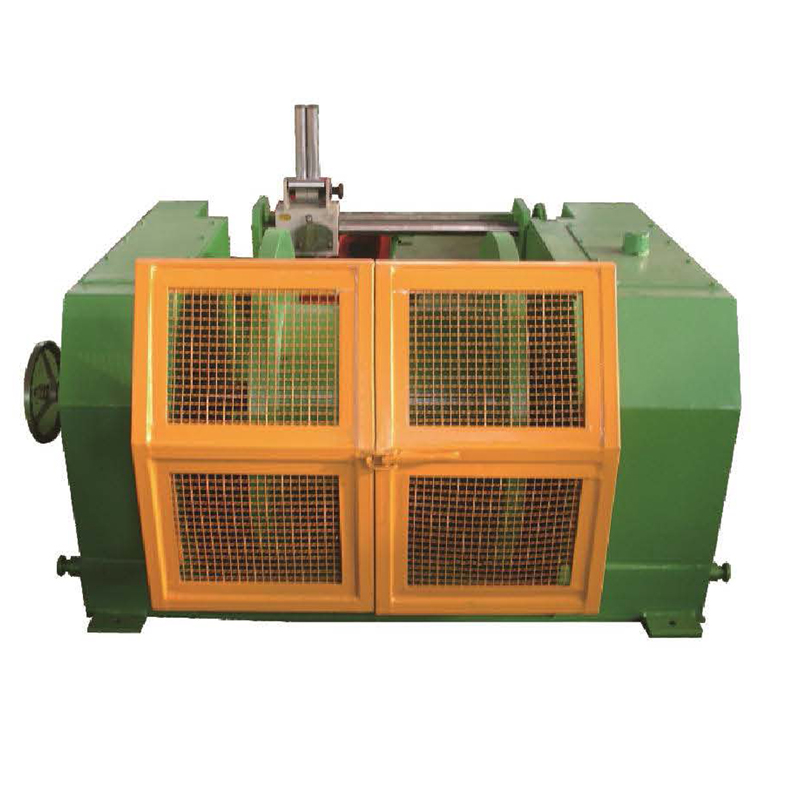

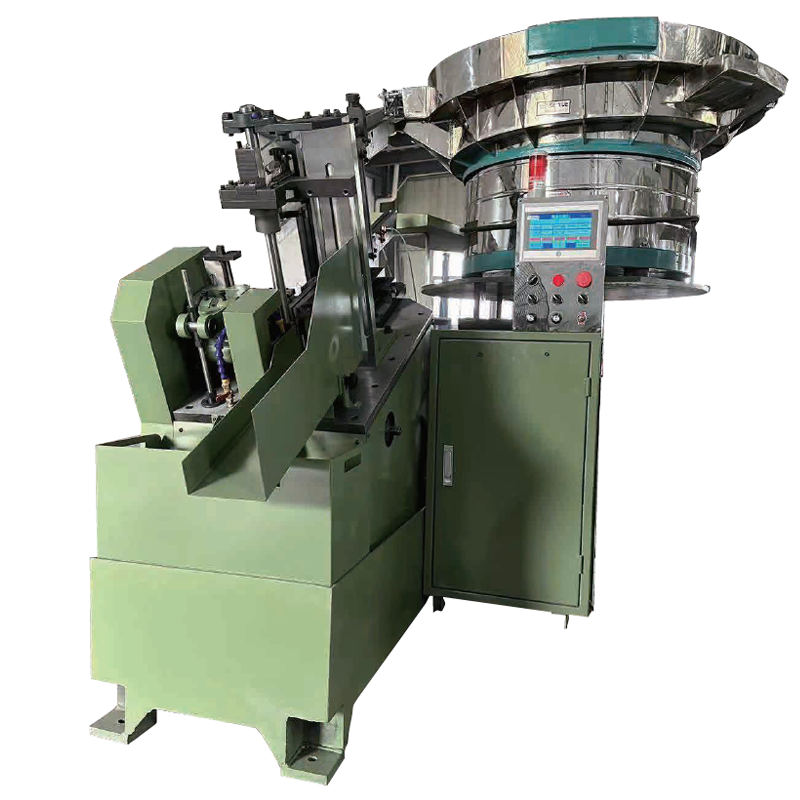

Explore efficient wire winding with our Spool Type Wire Winding Machine. Perfect for wire and cable industries, it ensures precise and uniform winding onto spools for streamlined wire handling.

Inverted Wire Drawing Machine specifications:

SG-300、SG-630、SG-1000 | ||||||

Type | SG-1250 | SG-1000 | SG-800 | SG-630 | SG-400 | SG-200 |

Spool size | 1250 | 1000 | 800 | 630 | 400 | 200 |

Wire winding diameter | Φ3.0-14 | Φ2.0-12 | Φ2.0-10 | Φ5.0-8.0 | Φ0.5-2.0 | Φ0.2-0.5 |

Motor's power | 22-30 | 18.5-22 | 15-18.5 | 11 | 7.5 | 5.5 |

Finished wire's coil weight | 2000-2500 | 1000-1500 | 500-1000 | 300-400 | 50-200 | 40 |

Advantages

Efficiency: Enhances productivity with efficient and uniform wire winding onto a variety of spool sizes.

Versatility: Accommodates different wire materials and spool types, offering adaptability to diverse wire winding needs.

Quality Output: Provides high-quality winding, maintaining wire integrity for subsequent processing and applications.

User-Friendly: Equipped with an intuitive interface, allowing easy parameter setting and real-time monitoring.

![1695271964633842.png C%)G9D6Y[U1KCR@8I`F}T]L.png](/static/upload/image/20230921/1695271964633842.png)

Our Shipping:

AFTER-SALES SERVICE:

1.The whole equipment is guaranteed for one year, and our companysupplies accessories for a long time.

2.To answer technical problems and provide technical services at anytime, three phone calls can not solve the problems, 24 hours to thefactory service.

3.Free training technology until users can independently producequalified products.

4.For all customers who purchase our equipment, our company willprovide the follow-up technical upgrade and improvement of theequipment free of charge.

FAQ:

Q1: What types of wire can be wound using the Spool Type Wire Winding Machine?

A: The machine is versatile and can handle various wire materials, including steel, aluminum, copper, and other metals commonly used in wire production.

Q2: Is the machine compatible with different spool sizes?

A: Yes, the machine is designed to be versatile and can accommodate a wide range of spool sizes, providing flexibility in wire winding operations.

Q3: How does the machine ensure uniform winding?

A: The machine is equipped with advanced technology that facilitates uniform winding of the wire onto the spool, ensuring consistent winding and high-quality output.

Q4: Can the winding parameters be adjusted for different wire types?

A: Absolutely! The Spool Type Wire Winding Machine comes with a user-friendly interface that allows operators to easily set and adjust winding parameters based on the specific wire type being used.

Q5: Is this machine suitable for large-scale wire winding operations?

A: Yes, the machine is designed to handle a significant volume of wire winding and is suitable for both small-scale and large-scale wire winding operations.

Q6: How easy is it to operate and maintain the machine?

A: The Spool Type Wire Winding Machine is designed for ease of use and maintenance. The user-friendly interface and robust construction make it simple to operate, and routine maintenance procedures are straightforward.